For more than 35 years, Loftin Equipment Co. has been in the engine business. In that time, we have seen many changes and regulations within our industry and have always provided our customers with the best products on the market. We put ourselves in their shoes, understanding their needs and what products will best suit their application.

As we enter Tier 4 Final, Loftin Equipment Co. has gone to great measures to ensure that we are on the cutting-edge in selecting the type of engines that meet stringent specifications and ensuring we have partnered with the right engine manufacturers. We have taken the time and investment to train our team on what is the best solution for our customers in selecting their Tier 4 Final engines and have the knowledge and technical engineering to work with them on preparing themselves for Tier 4 Final standards.

Customer Benefits From Tier 4 Final Standards

What you get:

- Re-engineering for and transitioning to Tier 4 Final

- The smallest engine footprint

- Tier 4 Final engines with the same footprint as Tier 4i

- Product and application assistance to build a better product

- Equipment with substantially lower operating costs over other engines

- Worldwide emission compliance with superior engine technology

With everything you want from an engine supplier:

- Answers to the complexities of Tier 4 regulations

- Quicker response and support

- Better lead-times

- The most robust, cost-effective technological solution to Tier 4 Final

Superior Technology

Loftin Equipment Co. provides the advantages of Kohler, Kubota® and Scania® technology. These manufacturers build engines designed for cleaner internal burning, which helps reduce the need for expensive exhaust after-treatment. Additionally, Kohler, Kubota and Scania products offer better fuel injection and internal combustion design, use of emission-control technologies (i.e., EGR and SCR), superior technology results in a smaller footprint, and lower applied costs.

Emission Control Technology

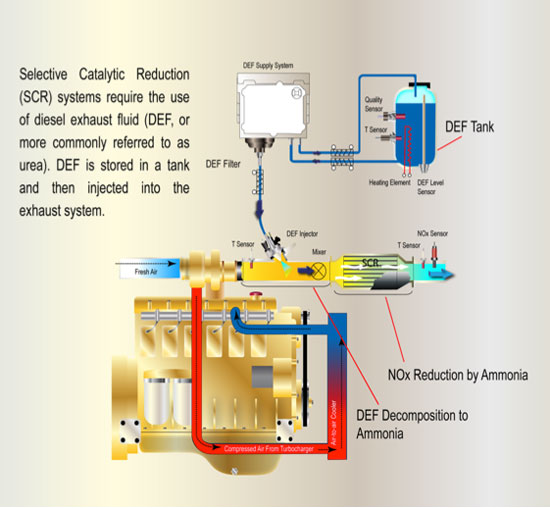

SCR – Selective Catalytic Reduction

- An after-treatment system

- Diesel Exhaust Fluid (DEF) solution is injected into the exhaust flow

- DEF commonly referred to as UREA

- Injection causes a catalytic process that reduces NOx

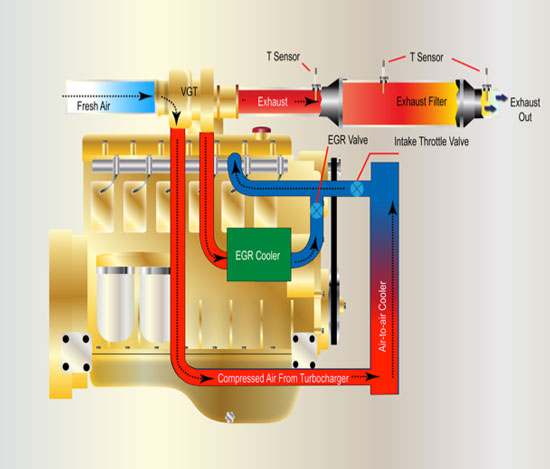

EGR – Exhaust Gas Recirculation

- Works in conjunction with variable vane geometry turbo charger (VGT)

- The intake air is diluted with exhaust gases

- Dilution reduces NOx formation during combustion

- Minimizes emissions to eliminate the need for particulate filters

- Used in conjunction with Diesel Oxidation Catalyst (DOC)

Tier 4 Final FAQs

Will we have to redesign our equipment to fit Tier 4 engines?

- The level of redesign will depend on your engine selections

- Engines that rely on DPF filters will need a greater space and footprint

- Loftin’s Kohler, Kubota and Scania engines have highly efficient combustion technology solutions

- Our Tier 4 final engine envelopes and footprints are much smaller than other engines as such requiring minimal equipment redesign

- Loftin offers Kohler (56hp to 102hp) Kubota (6hp to 114hp) and Scania engine models (200hp to 770hp)

What is the final emission level?

- Tier 4 Final is what it states – FINAL (Further standards not planned)

- The EPA have been advancing emission certification since 1996

- Phased in over 18-years, each Tier became much more stringent

- Tier 4 Final will will result in nitrous oxide (NOx) and particular matter (PM) emissions being 99% cleaner than they were originally

- EPA Tier 4 final by 2014

- Particular Matter (PM) -.02 g/kWm – hour

- Oxides of nitrogen (NOx) – 0.4 g/kWm – hour

- Non-methane hydrocarbon – 0.019 g/kWm – hour

- Carbon monoxide (CO) – 3.5 g/kWm – hour

When do we require Tier 4 engines?

- Flexing allows OEMs to use engines certified to lower Tier standards

- Flexing was calculated on the level of total engine production

- Most OEMs are using up their flex engines

- If flex engines are not available OEMs will have to use Tier 4 Final engines starting January 1st 2014

- Kubota and Scania Tier 4 Interim engines will see little change as they move to Tier 4 Final

Which technology best addresses Tier 4 Final?

- Engine manufacturers used three technologies to address Tier 4

- SCR (Selective Catalytic Reductions)

- EGR (Exhaust Gas Recirculation)

- DPF (Diesel Particulate Filters)

- Engine manufacturer that developed more advanced internal engine emission control avoided reliance on DPF technology

- Kubota and Scania have the best technology by more advanced designs with EGR and SCR technology

What are the cost implications of Tier 4?

- Tier 4 engines will be more expensive if they use EGR, SCR, and DPF

- The biggest cost impact to OEMs is the cost of DPF technology and the reengineering to accommodate increased engine footprint

- The single biggest cost increase is the DPF impact

- Loftin advanced engine offering limits requirement for DPF.

- Scania does not require DPF, nor does Kubota below 25 hp

What are the service and operation issues of new technology?

- SCR urea solution will have to be monitored and topped up

- Solution needs a heating via an element in supply tank when used in low temperatures

- The Loftin solution means minimum service impact over current engine technology

- DPF policy regarding Kubota Tier 4 Final engines above 25 hp

- Free exchange of the DPF within initial 3000 hours or cleaning

- Exchange DPFs will be inventoried at Loftin and approved dealers

- A Diagmaster and laptop will be used to reset and check the ECU

- Loftin technicians are fully trained to undertake DPF maintenance

What does Tier 4 do for us?

- All your equipment can be sold in the United States

- Your equipment will be powered by engines having the latest in technology for the least emissions

- Tier 4 Final engines allow equipment to be sold in other regulated emission markets such as Europe and Japan

- No restriction on sales due to emission regulations

- Selection of Loftin, Kubota and Scania will enhance your equipment and lead to increased sales and market share

Why partner with Loftin for your Tier 4 needs?

- Engines with less cube and smaller foot print

- Less DPF filters – Meeting emissions with virtually no increase in engine “footprint”

- Kubota and Scania engines are compact and impressively streamlined, making them ideal to build into any application

– Superior internal engine technology:

- Electronic Management Systems (EMS) cuts fuel consumption and emissions

- Value-adding technical features ensure maximum reliability

- Powered equipment is less expensive to maintain and operate

– The best cost solution:

- Engine technology that adds the least cost to the engine in attaining Tier 4 final

- Avoid the costs of major re-engineering to apply Tier 4 final engines

- Engine technology with reduced operational and maintenance costs

What is flexing?

- Low volume equipment manufacturers can use Tier 4 Interim engines in lieu of Tier 4 final

- Single Engine Family – OEM may produce up to 700 units with flex engines within a power category during the 7-year period – No more than 200 units in any single year within a power category

- Multiple Engine Family – OEM may produce up to 525 units with flex engines within a power category during the 7-year period – No more than 150 units in any single year within a power category

- Granted to equipment manufacturers to give them some relief in launching engines meeting new emission regulations